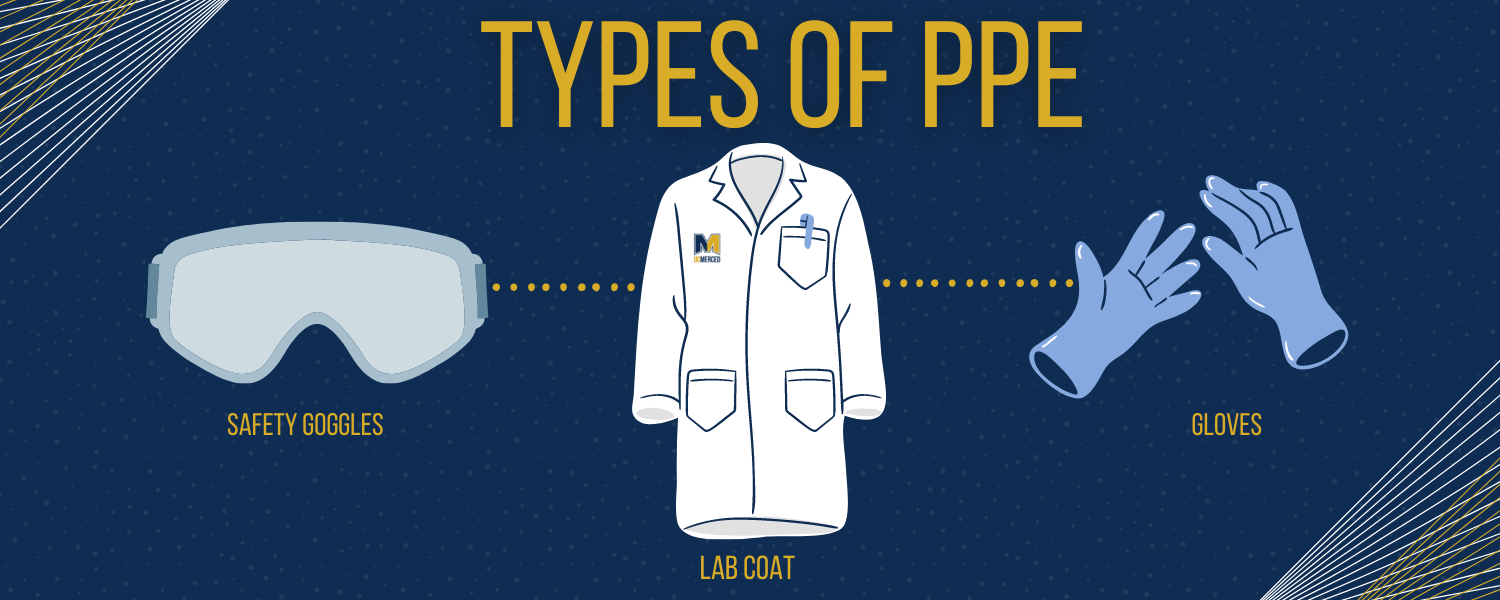

Selecting the right PPE to sufficiently reduce exposure to hazards is essential to laboratory safety. The purpose of this section is to provide resources allowing researchers to identify and classify various types of PPE so the appropriate safety precautions are taken when conducting research.

For the purpose of this site, PPE will be classified into categories: eye and face protection, hand protection, body protection, respiratory protection, and hearing protection. Each category includes its own corresponding safety equipment that will be described below.

Eye protection is achieved by wearing eyewear specifically designed to reduce the risk of exposure to chemical splashes, laser radiation, and/or flying debris. There are four primary types of eye protection — of which each has its own limitations — including general safety glasses, laser safety glasses, chemical splash goggles and impact goggles. Full face protection is achieved by wearing face shields.

| Type | Use | |

|---|---|---|

| General safety glasses |

|

|

| Laser safety glasses |

|

|

| Chemical splash goggles |

|

|

| Impact goggles |

|

|

| Face shields |

|

|

| ↑ Return to top of page | ||

Appropriate selection of gloves is essential to protecting hands. Chemically protective gloves are one of the most important tools to minimize dermal exposures to chemicals in research laboratories. Gloves should only be used under the specific conditions for which they are designed, as no glove is impervious to all chemicals.

It is also important to note that gloves degrade over time, so they should be replaced as necessary to ensure adequate protection. Laboratory personnel should use the information below, and manufacturer compatibility charts (found under useful resources in the above right menu), to choose the type and style of glove.

| Type | Use | ||

| Light latex, vinyl or nitrile gloves |

Disposable latex (powdered or unpowdered) |

Working with biological hazards (human blood, body fluids, tissues, bloodborne pathogens, specimens), BSL1, BSL2, BSL2+, BSL3 |  |

| Disposable nitrile (puncture and abrasion resistant, protection from splash hazards) | Working with biological hazards and chemical splash hazards |  |

|

| Disposable vinyl (economical, durable, similar to latex) | Working with biological hazards, BSL1, BSL2, BSL2+, BSL3 |  |

|

| Light chemical resistant gloves | Natural rubber latex (chemical resistant, liquid-proof) | Working with small volumes of corrosive liquids, organic solvents, flammable compounds |  |

| Light to heavy chemical resistant gloves | Nitrile (chemical resistant, good puncture, cut and abrasion resistance) | Using apparatus under pressure, air or water-reactive chemicals |  |

| Heavy chemical resistant gloves | Butyl (high permeation resistance to most chemicals) | Working with large volumes of organic solvents; small to large volumes of dangerous solvents, acutely toxic or hazardous materials |  |

| Viton® II (high permeation resistance to most chemicals) | Same as butyl gloves, plus hazardous material spills |  |

|

| Silver shield (extra chemical and mechanical protection) | Same as butyl and Viton® II gloves, added mechanical protection, hazardous material spills |  |

|

| Insulated gloves | Terrycloth autoclave (heat resistant) | Working with hot liquids and equipment, open flames, water bath, oil bath |  |

| Cryogen (water-resistant or waterproof, protection against ultra-cold temperatures) | Handling cryogenic liquids |  |

|

| Wire mesh gloves | Wire mesh (cut resistant) | Working with live animals and exposed to potential cuts |  |

| ↑ Return to top of page | |||

Lab coats are required for all wet labs. Cotton or cotton/poly blends are sufficient for labs without risk of fire. Nomex coats are required for work with pyrophorics, flammable liquids in quantities of more than 4 liters, or when work involves flammable liquids and an ignition source such as a burner. Barrier coats must be worn when working with infectious materials. Barrier coats can be autoclaved by placing the coats in a pan and placing an additional pan of water in the autoclave.

| Type | Use | |

| Traditional (cotton/cotton-polyester blend - protects skin and clothing from dirt, inks, non-hazardous chemicals) | General use; chemical, biological, radiation, and physical hazards |  |

| Flame resistant (e.g. Nomex or other flame-resistant cotton — resists ignition) | Working with water or air reactive chemicals, large volumes of organic solvents, and potentially explosive chemicals |  |

| Barrier (predominantly polyester — offers splash protection, not flame resistant) | Working with infectious materials |  |

| ↑ Return to top of page | ||

Program Procedures

Respiratory protective equipment is only used as a "last line of defense," and as a result, requires individual assessment and training by EH&S personnel. Proper fitting and use is key to respirator efficacy, so EH&S requires all individuals who believe one or more of their job tasks require respiratory protective equipment to contact EH&S. The following steps will be taken:

- A workplace hazard assessment will be performed to determine if the task requires respiratory protective equipment.

- If the task does not require respiratory equipment but the employee wishes to use such equipment, he or she must complete Appendix D of the Respiratory Protective Equipment Manual and return the bottom portion of the form to EH&S. This form provides information in accordance with OSHA Sec. 1910.134 regarding voluntary use of respirators when not required under the standard.

- If respiratory protective equipment is necessary, the employee will be given a medical evaluation questionnaire to fill out as well as a supplement to the medical questionnaire that outlines the findings of the hazard assessment conducted by EH&S. Both forms should be taken to a contract physician or licensed health care professional (PLHCP) who will perform a confidential medical evaluation to determine the employee's fitness to wear a respirator.

- When the employee is approved to wear a respirator for the job task(s) outlined in the hazard assessment, the appropriate respirator will be selected and the employee will be fit-tested following CAL/OSHA's accepted fit-testing protocol. Fit-testing assures the selected respirator is worn correctly to allow proper performance.

- During fit-testing, the employee receives training on the appropriate method(s) to store, handle and sanitize the respirator.

- Once initial fitting and training are completed, the employee must enroll in and attend yearly training conducted by EH&S through the UC Learning Center. Employees will be authorized to register for the "Basic Respiratory Protection" course to fulfill the annual training requirement.

| Type | Use | ||

| Surgical masks | Protect against large droplets and splashes (does not require fit-testing) | Working with live animals; working with infectious material in BSL-2+ level labs but only protects your sample from you, not the other way around. |  |

| N-95 respirators | Protects against dust, fumes, mists, microorganisms (requires fit-testing) | Working with live animals or infectious materials in BSL-2 level labs with known airborne transmissible disease (e.g. tuberculosis, also required for influenza (flu)); dusty environments |  |

| Half-mask respirators | Purifies air: protects against a variety of particulates, vapors, dust, mists, fumes; depends on filter cartridge used (requires fit-testing) | Working with live animals or infectious materials with known airborne transmissible disease; dusty environments; chemical vapors; particulates |  |

| Full-face respirators | Same as half-mask, with greater protection factor; eye, mucus membranes, and face protection; depends on filter cartridge used (requires fit-testing) | Working with live animals or infectious materials with known airborne transmissible disease; dusty environments; chemical vapors; particulates |  |

| Respirator cartridges | For use in half-mask respirators and full-face respirators |

|

|

| ↑ Return to top of page | |||

All laboratory personnel shall contact EH&S to request noise monitoring in their laboratory settings to perform noise monitoring and advise on the specific use of hearing protectors.

Laboratory workers whose eight-hour time-weighted average noise exposure exceeds the 85 dBA Action Level will be enrolled in the UC Merced Hearing Conservation Program. These individuals will receive annual audiometric testing, will have hearing protectors made available to them by their supervisors, and will be provided training on the fitting, use and care of these devices.

Monitoring results for individuals whose noise exposure exceed the Action Level will also be notified in writing using Attachment B — Noise Monitoring — Dosimetry Results.

| Disposable earplugs | Polyvinyl chloride (PVC) or polyurethane foam, one-time use design (no cleaning), one size fits all, lightweight, low cost, blocks all sound. Useful when working in areas where sound levels average over 85 dBa; EH&S can assist in assessments |  |

| Reusable earplugs | Silicone tapered fit, reusable (needs cleaning), corded or uncorded, lightweight, more durable than disposable earplugs. Useful when working in areas where sound levels average over 85 dBa; EH&S can assist in assessments |  |

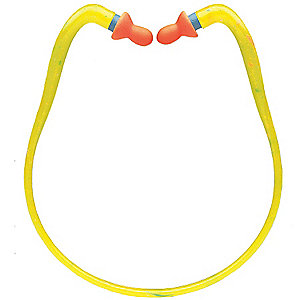

| Hearing band | Earplugs connected to a flexible band that can be worn around the neck when not needed. Useful when working in areas where sound levels average over 85 dBa; EH&S can assist in assessments |  |

| ↑ Return to top of page | ||